Taylor’s Bell Foundry Tour

Loughborough has been home to the historic bellmakers John Taylor & Co since 1859. Bells from the foundry can be found in over 100 countries around the world. Some of the biggest bells cast at Taylor’s can be found across various sites in the UK. For example, big bells named Little John at Nottingham Council House, Old Market Square, Great George at Bristol and famously Great Paul in St Paul’s Cathedral in London.

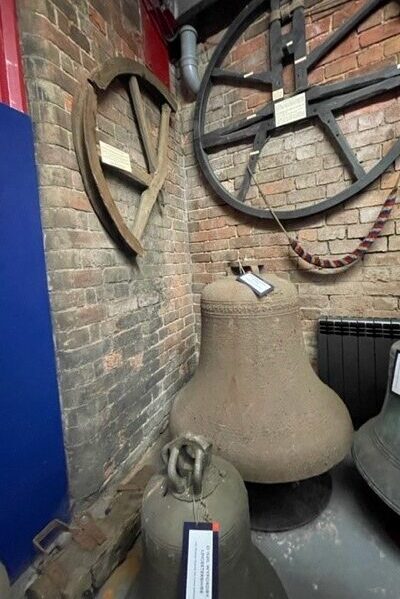

I was invited by Loughborough Bell Foundry Trust on a guided tour led by John, a volunteer with over 50 years bellringing experience and a great interest in the making and preservation of bells. John explained the process of repairing bells and fittings, such as headstocks. We were taken to the workshop where the team were busily working away grinding headstocks with precision, painting parts and moving bells. It was explained how a bell works with the aid of a headstock, wheel and rope.

Bellfoundry Tour

The tour included a visit to the carpentry workshop to see how the wheel structures and other fittings are made. Here there was a wooden Clavier made and packaged for shipment to the USA. A Clavier is a wooden machine that operates the bells rather than a human rope pulling system. The machine has various wooden arms that are struck to ring different bells, it looks a bit like an organ.

It was on to the tuning workshop to learn more about the type of metal used for bells such as how and why bell metal is the best choice for the tune of the bell. Tuning a bell is now carried out by machine. Historically they were struck and chipped on the edges to produce the desired sound.

The Museum Collection

It was back to the museum where Curator, Chrissie described the history and variety of the collection. We were shown snippets from the rare complete operational records archive on display in the main museum area. There were ledgers, photos and articles telling the story of the Taylors and its workforce.

We were then shown the Museum Bell Room where every bell on display could be played. Here there were examples of bells from the 14th century up to more recent times, including a very sombre lower grade bell made for executions at Stafford Jail…

Bell Casting

The highlight of the tour was a chance to see a set of bells being cast in the forge. The metal was heated in a furnace and then poured into moulds to cast the bells. The moulds are dug into sand to ensure a slow cooling of the metal for optimum bell production.

Did you know the meaning of the word dross comes from the unwanted material that forms on top of molten metal?

The museum is open to guided tour visitors and times and booking information can be found here. They also offer school visit options with some great handling opportunities, a great way to introduce the young people to a fascinating STEM (Science, Technology, Engineering and Maths) topic.

Preserving the art of bell making is something very much on the mind of the trust who work closely with the Heritage Craft Association to look at ways to draw more young people in to the profession and to encourage wider diversity in the field. If you are interested in apprenticeships do get in touch with them.

If you enjoyed reading more about Taylor’s Bell Foundry Tour and you are interested to read more on the history of how things are made – take a look at the Heritage Hiker’s Guide. History in the Making. Gin or Heritage Hiker’s Guide. History in the Making. Porcelain.

Upcoming Events

Book your space on these upcoming events

SWAW October Walk around Barry Island

📅 5 October, 2025

Book Here